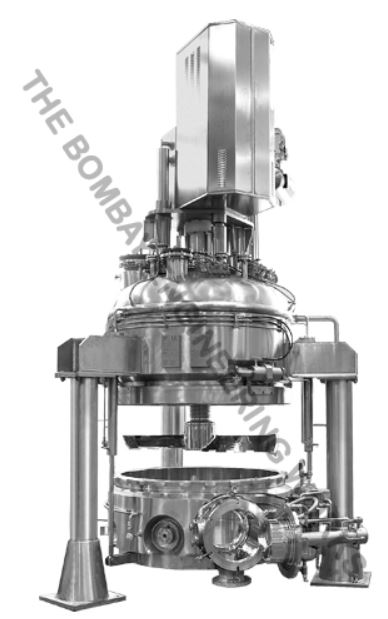

The Agitated Nutsche filter dryer (anfd) filter or agitated nutsche dryer is a Nutsche type filter designed to separate liquids’ solids. It is enclosed and generally operated under pressure or vacuum. Additionally, the equipment is fitted with a stirrer mechanism that efficiently agitates the slurry during cake washing, squeezes the cake during filtration, and assists in the cake’s automatic discharge.we are agitated nutsche filter manufacturer in india. we are one of the best manufacturing company in vasai for pharmaceutical product

Agitated Nutsche Filter-Dryer (ANFD) is a versatile solid-liquid separation equipment that can filter, wash, re-slurry and dry your product in a single charge and in a fully enclosed vessel.

- Available in sizes ranging from 20 Litres to 20,000 Litres

- Large number of variants are possible with options for cGMP, Pharma and Sterile applications

- We offer a range of MOCs including Stainless Steel, Hastelloy®, other Nickel based and exotic alloys and also cladded, polymer-lined or glass-lined construction

- Suitable for a large majority of chemical products. Lab and pilot scale trials are also available.

HLE Glascoat is the largest manufacturer of ANFDs globally and is the pioneer in India for Stable Drive Systems, Sterile construction and special process features in filters and filter-dryers.

Agitated nutsche filter dryer working principle are as follow-

Agitated Nutsche Filter and dryer is a closed vessel designed to separate solid and liquid filtration under pressure or vacuum. The closed system ensures odorless, contamination-free, and non-polluting working conditions, maintaining product purity and hygiene. A typical unit consists of a dished vessel with a perforated plate. The entire vessel can be kept at the desired temperature by using a limpet jacket, jacketed bottom dish, and stirrer (blade and shaft) through which heat transfer media can flow. The vessel can be made entirely leak-proof for vacuum or pressure service. Agitated Nutsche filters are used widely in the production processes of pharmaceutical, chemical, and laboratory industries. They are manufactured as agitated Nutsche filter dryers (ANFD’S) for the filtration and drying in the same unit of active pharmaceutical ingredients (API) and chemical compounds.

The Agitated Nutsche Filter consists of a cylindrical shell with a top dished and welded flat bottom. The base plate is stiffened by supports welded under the base plate. The base plate is having an arrangement of a bolting bar to hold the filter cloth. Suitable support mesh is provided under filter cloth to facilitate the flow of the filtrate. Suitable nozzles are provided, including Manhole and Side discharge nozzle. The solid bar is used for the Agitator shaft and solid plate for blades made in specially “S” curved to take high torque generated during solid discharge and re-slurring operation.

Drive assembly consist of Motor with Speed reducer, Lantern assembly with Stuffing-box/Mechanical Seal is provided. A manual/Hydraulic system is provided for the movement of the agitator and discharge Valve. Control Panel with Motor control relay, fuse indicating lamp which will be installed in the safe area.

FOLLOWING ARE STEPS INVOLVED IN THE PROCESSING OF AGITATED NUTSCHE FILTER dryer WITH AGITATOR AND DISCHARGE VALVE: –

1) Filtration

2) Washing of Filter Cake

3) Repeat mix or washing of the cake

4) Convection drying of the cake

5) Smoothing with compression of the cake

6) Fully Automatic discharge of the wet or dried cake.

Material:

Stainless Steel, Carbon Steel, Hastelloy, Rubber, or Plastic-coated Steel.

FILTER MEDIA

Sintered metal multi-ply of Textile.

SIDE DISCHARGE UNIT

Provided with hydraulically actuated door, sight glass, switch for safety locking, sealing arrangement with O-ring.

ADVANTAGES

- Vacuum or pressure filtration possible.

- The inert gas atmosphere can be maintained.

- Minimal contamination of the cake.

- Very high solvent recovery.

- Considerable saving in manpower.

- Solvents are in closed systems, so no toxic vapors are let off in the atmosphere.

- Personal safety is maintained, and heat transfer surfaces can be provided to maintain filtration temperature.

- The minimum hold up of filtrate in the equipment

- Reduced workforce & no manual handling of the product

- The Agitator moves clockwise, anticlockwise, up and down. This ensures thorough washing and re-slurring of the cake.

- Toxic and hazardous material can be processed.

- Product purity maintained

- Blending of product possible before discharging

- The product can be washed thoroughly and economically with solvents.

- Complete automation with PLC is available.

- Combining filtration, washing, re-slurry, and drying in one fully enclosed, automated unit permits reduction of capital and operating costs.

- Heat transfer surface can be provided on the vessel wall by providing a Jacket or Limpet Coil. Indirect Heating can be provided on the Filter base and Agitator.

- Large quantities can be processed faster than the conventional systems.

- The number of conventional machines employed for the filtration process is also reduced.