DESCRIPTION :

An essential prerequisite for the safety of a drug or medicine is sterility. The design of pharmaceutical autoclave steam sterilizers is consistent with the most current recommendations and guidelines, cGMP, GAMP, and FDA, to assist customers in complying with the production process’s stringent requirements. We offer a wide range of steam sterilizer autoclave solutions featuring multiple sterilization methods and single or double door sterilizers with a sufficient volume of a few hundred liters to large-scale systems with magnitudes of up to 60 m3.

Autoclaves is also known as steam sterilizers and are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an appropriate sterilization temperature for a given amount of time. The steam in the steam efficiently transfers heat to the items to destroy the bacteria and spores’ protein structure.

In healthcare, the term “autoclave” is typically used as the nomenclature to describe a Steam Sterilizer. ANSI/AAMI4, which provides standards and guidelines for the processing of medical devices.

Working of Autoclave Steam Sterilizer

Autoclaves are commonly used in healthcare settings to sterilize medical devices. The items to be sterilized are placed inside a pressure vessel, commonly referred to as the chamber. Three factors are critical to ensuring successful steam sterilization in an autoclave: time, temperature, and steam quality.

To directly connect with us click here

USES :

Sterilizers are ideal for Hospitals, Research Laboratory, and other Pharmaceutical Industry. They are designed for the safe & efficient sterilization of various items such as Ampoules & Vials, Rubber goods, empty flasks, instruments & utensils, Fabrics wrapped or unwrapped, etc.

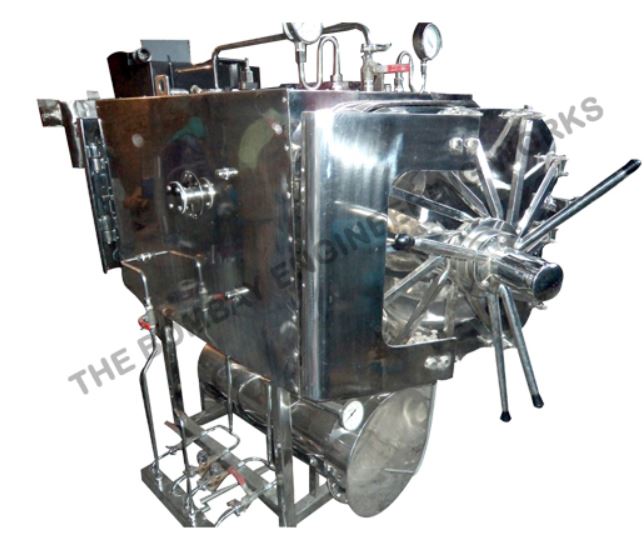

CONSTRUCTION :

The Chamber is constructed of heavy-duty stainless steel 316 to withstand the pressure of 2.2 Kg/cm2 corresponding to a temperature of 1340 C and also to withstand a vacuum of 650-700 mm (26″/28″) of Hg. in Chamber.

Two rails are provided in the chamber bottom for easy loading & unloading of the Carriage material.

DOORS :

The Sterilizer helps supply with a single door or double doors made of 304/316 S .S. The doors have automatic sliding-type arrangements OR Manual Hinge type doors.

The doors will have a unique arrangement to open them manually in case of power failure.

The door Gasket will be of Silicon Rubber.

Generally, there are three phases to the autoclave process:

1] Conditioning Phase (C): Air inhibits sterilization and must be removed from the chamber during the first phase of the sterilization cycle, known as conditioning. In dynamic air removal-type steam sterilizers, the air can be removed from the chamber using a vacuum system. It can also be removed without a vacuum system using a series of steam flushes and pressure pulses. Gravity-type sterilizers use steam to displace the air in the chamber and force them down the sterilizer drain.

2] Exposure Phase (S): After the air is removed, the sterilizer drain closes, and steam is continuously admitted into the chamber, rapidly increasing the pressure and temperature inside to a predetermined level. The cycle enters the exposure phase, and items are held at the sterilization temperature for a fixed amount of time required to sterilize them.

3] Exhaust Phase (E): During the final phase of the cycle, exhaust, the sterilizer drain is opened, and steam is removed, depressurizing the vessel and allowing the items in the load to dry.

Quality steam is vital to a successful autoclave sterilization process. The steam used for sterilization should be composed of 97% steam (vapor) and 3% moisture (liquid water). This ratio is recommended for the most efficient heat transfer. When the steam moisture content is less than 3%, the steam is described as superheated (or dry). Superheated steam is too dry for efficient heat transfer and is ineffective for steam sterilization.

The temperature inside an Autoclave Steam Sterilizer

Commonly recommended temperatures for steam sterilization are 250° F (121° C), 270°F (132°C) or 275°F (135° C). To kill any microorganisms present, the sterilized items must be exposed to these temperatures for the minimum time recommended by the manufacturer of the device being processed.